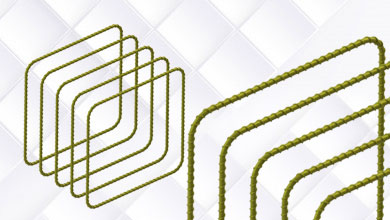

Fiber Rebar High Compressive Strength, Durability and Low Cost

Fiber FRP Rebar is a concrete reinforcement that has higher strength than steel, is lighter, tested and approved, non-corrosive, usable in different areas. Regbar designs and manufactures innovative structural solutions based on high-tensile FRP (Fiber Reinforced Polymer) bars and profiles.

Creative Approach

Regbar FRP Rebar is a concrete reinforcement that has higher strength than steel, is lighter, tested and approved, non-corrosive, usable in different areas. Regbar designs and manufactures innovative structural solutions based on high-tensile FRP (Fiber Reinforced Polymer) bars and profiles. Those solutions can be either made Glass-Fiber based (GFRP) or Carbon-Fiber based (CFRP). Regbar offers both GFRP and CFRP bars according to your needs.

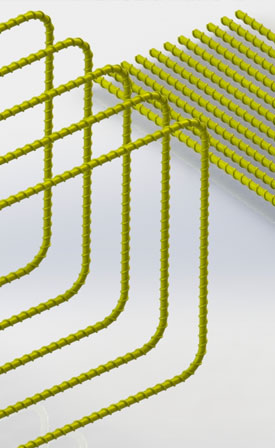

Regbar Fiber Rebar is an ideal solution forbridges, subway soft-eye applications, areas under magnetic fields at hospitals, concrete roads, bridge decks, bridge kerbs, pier covers, sidewalks, barrier walls, sound barriers, airport taxiways, water supply and treatment plants, wave breakers, piers and sets, ports, parking garages, salt depots, swimming pools, industrial areas, desalination entries etc.

Product Design

Concrete has been used as construction material due to its high compressive strength, durability and low cost for a long time. However, its known weaknesses are brittleness and limited tensile strength. This has been overcome by using steel reinforcement bars (rebars) on the tension side of concrete constructions.

Application

It is ideal in hospitals for MRI machine pads, research facilities, aluminum smelters, industrial facilities, underground electrical enclosures, switchyards, toll roads, monorail tracks, etc. Also it is widely used in TBM soft-eyes, diaphragm walls, drilled pile walls, formwork anchors, temporary structures, rock anchors, soil nails.

Main Advantages

Corrosion Resistance • Robustness • Durability • Easy placement & Easy cutting • Electromagnetic neutrality • Lightness Greater tensile strength than steel • Transparent to magnetic fields and radio frequencies • Electrically and thermally non-conductive • Chloride ion and chemical attack impermeable

Main Advantages

Corrosion Resistance

Robustness

Durability

Easy placement

Electromagnetic neutrality

Lightness Greater tensile strength than steel

Transparent to magnetic fields

Electrically and thermally non-conductive

Chloride ion and chemical attack impermeable

Fiber Rebar

Regbar Fiberglass Composite Rebar (FRP Composite Reinforcement) is a composite reinforcement used instead of corroded classic steel reinforcements. It has higher strength than steel, lighter, tested and approved. It can be used in many fields.

Fiber Rebar Application

It is ideal in hospitals for MRI machine pads, research facilities, aluminum smelters, industrial facilities, underground electrical enclosures, switchyards, toll roads, monorail tracks, etc.

FIBERGLASS COMPOSITE REBAR FRP COMPOSITE REINFORCEMENT

It is not affected by salt, chemical substances and the alkalinity in the concrete.

– When V.ROD reinforcement rod is used in structures exposed to de-icing salt, seawater and chemical substances, the structure will have a longer life-span.

-Regbar Fiber Rebar is an ideal solution forbridges, subway soft-eye applications, areas under magnetic fields at hospitals, concrete roads, bridge decks, bridge kerbs, pier covers, sidewalks, barrier walls, sound barriers, airport taxiways, water supply and treatment plants, wave breakers, piers and sets, ports, parking garages, salt depots, swimming pools, industrial areas, desalination entries etc

Areas of Usage

Other Products

© 2020 All rights reserved. Powered By Regbar Construction